VT

Type P-011FLM

Description: VT P-011FLM The single-channel pyroelectric flame detector is based on the pyroelectric effect of lithium tantalate (LiTaO3) single crystal, with ultra-low impurity.

The detection circuit is composed of a field effect tube and a high-resistance gate resistor system; it is packaged in a TO-5 metal tube; it uses a precise narrow-band filter.

The film is an infrared optical window; the combined use of Saiyan Sensing Technology single-channel pyroelectric reference detector can better eliminate the sensor system errors for more accurate detection.

Can be widely used in flame detection.

Features: 1.High single channel

2.Quick response

3.Small and medium space detection

4.Cost-effective

◆Product application

-Flame detection

◆Maximum rated temperature

| Parameter | Typical Value | Unit |

| Operating Temp. | -40~85 | ℃ |

| Storage Temp. | -40~85 | ℃ |

◆Product specification

| Parameter | Typical Value | Unit | Remarks | |

| Parameters of Filter | 4.9*4.9 | mm | ||

| Compensation film | Yes | |||

| Field of View | Min. | 120 | ° | |

| Voltage Responsivity | Typ. | 900 | V/W | (500K、10Hz、25℃、without filter/window) |

| Noise | Max. | 500 | nV/√Hz | 10 Hz |

| Detection rate | Typ. | 5.0*108 | cm*Hz1/2*W-1 | (500K、10Hz、25℃、without filter/window) |

| Thermal Time Constant | Typ. | 150 | ms | |

| Electrical Time Constant | Typ. | 4 | s | |

| Operating Voltage | Typ. | 2-15 | V | Recommended: 3-5V |

| Source Voltage | Typ. | 0.2-1.5 | V | |

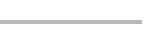

◆Filter spectral characteristics

| Infrared Channel Filter1 F3.40 | ||||

| Parameter | Symbol | Typical Value | Unit | Remarks |

| Center wavelength | CWL | 4300±40 | nm | |

| FWHM | HPB | 600±40 | nm | |

| Peak transmittance | Tpeak | ≧85 | % | |

| Cut-off area | Tpavg | ≦1 | % | From UV to 11um |

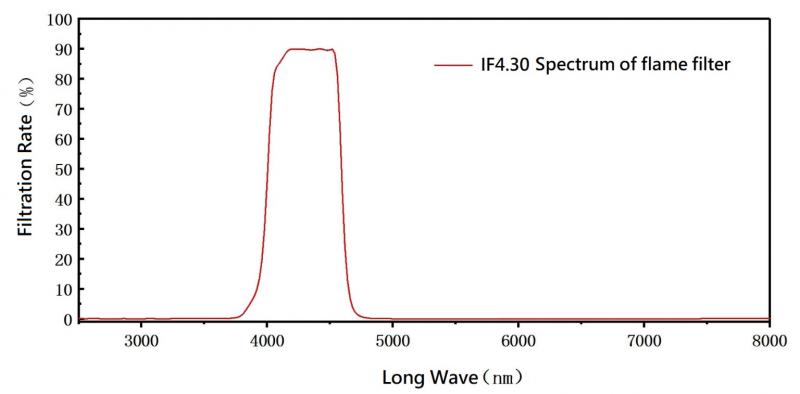

◆Dimension

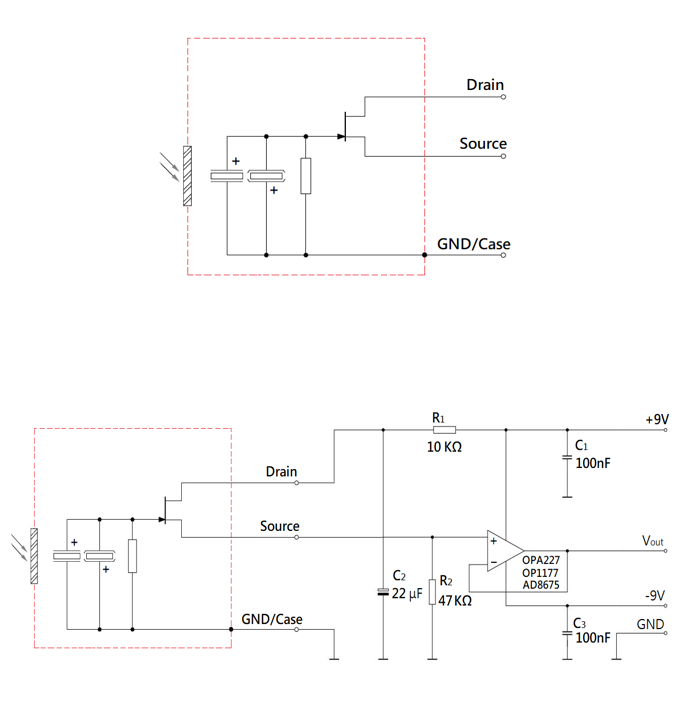

◆Detector internal circuit

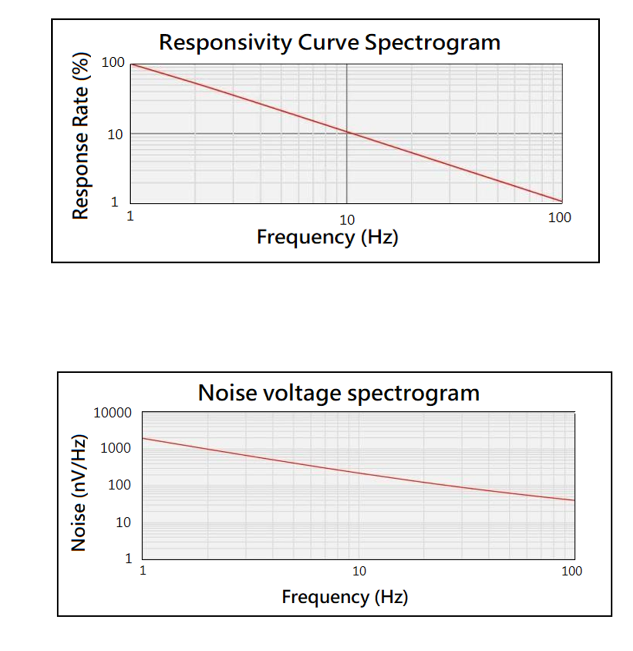

◆Detector spectral characteristics

◆Precautions

1.Pyroelectric infrared detector is a typical AC working device. When the target is still and

the temperature is constant, the pyroelectric infrared detector has no signal output.

The signal is only output when there is a transient target movement, or a temperature change, or modulation with a chopper.

2.In the process of operating, using and storing the pyroelectric infrared detector,

avoid rapid temperature changes. When the temperature change rate is less than 1°C/min, the detector can keep working normally.

If the detector heats up too fast, it may cause damage to the lithium tantalate slide.

3.Pyroelectric infrared detectors are piezoelectric and are very sensitive to sound,

electromagnetic waves, and vibrations. When using pyroelectric infrared detectors, proper shock absorption and shielding are necessary.

4.When welding the pyroelectric infrared detector, it is recommended to weld at a position

above 4mm, the welding time should be as short as possible, and use,the tweezers clamp the root of the pin to help dissipate heat and prevent the sensitive element of the detector from being damaged.

To prevent components from falling, and pay attention to electrostatic protection, spare components should be kept dry.

5.When operating the pyroelectric infrared detector, due to hand contact, especially after

welding, the temperature of the pyroelectric infrared detector body has been changed,

so when the detector works again, it needs to wait for a period of time until the detector body Normal operation can only be resumed after the temperature has equilibrated.

After the detector is warmed up, if the power is turned on immediately, the detector may be in a cut-off state at this time.

6.The operating environment of the detector should be kept clean and tidy. Avoid touching the filter directly with hands or hard objects, and keep the window clean.

7.Avoid damage to the airtightness of the detector caused by force on the foot of the base of the detector.